References

As a reference we have listed below some of our main projects.

MOL Plc. Danube Refinery Tank Farm reconstruction.

|

At MOL Plc. around the year 2000 the reconstruction of the storage plants was require. There were several units that needed upgrading and refurbishing. New level measuring systems were developed and also some new motor operated valves were installed, mainly controlled, via Rotork Fieldbus, in order to control the oil and product movements. Procoplan Ltd. involvement in this project was the preparation of Instrumentation Design plans and the DCS software. The main features in this project were:

- The Honeywell TCS3000 DCS instrumentation system

- The IO numbers: xxxx, the Rotork equipment numbers: xxx

|

|

|

MOL Plc. Danube Refinery Gasoil Desulphurization Plant.

|

To conform to the European Union’s environmental protection standard for desulphurization of gasoil products a new plant was built between 2002 – 2004 within the Danube Refinery site. Procoplan Ltd. played a large role in the preparation of the instrumentation design plans as well as in the DCS software design. The main features of this project were:

- Emerson DeltaV control system.

- Physical IO numbers: 2000 of which 200 were Foundation Fieldbus IOs

- HIMA safety PLC (1000 signals)

|

|

|

Zugló-Therm Ltd. Füredi street, gas powered engine, residential power plant.

|

In 2004 – 2005 a gas engine small power plant was established securing the heating and hot water supply for 18 thousand households in Zugló.

By appllication of gas engines, electrical and heat energy can be produced at the same time by co-generation

The completed powerplant consists of 3 gas engines and have the total electrical power of 18 MW, and heat production of 17,1 MW. Procoplan Ltd. participation in this project was the preparation of Instrumentation design plans for the Ventilation and Gas Alarm System and the installation it’s software configuration. The project’s main features were:

- Yokogawa Stardom control systems with Fast/Tools HMI

- IO numbers: 50 pcs AI/AO, 230 DI/DO

|

|

|

Hungrana Ltd. – Establishment of a Bioethanol Plant

|

At the Hungrana Starch and Isosugar Manufacturing and Trading Co. Ltd in Szabadhegyháza a new Bio ethanol plant was established. The instrumentation and electrical design plans of the new plant were completed by Procoplan Ltd. The main features of the project were:

- Yokogawa CS3000 DCS control system.

- IO numbers: 150 pcs. of AI/AO and 1100 pcs. of DI/DO.

- Installation of a new 0.4KV electrical distribution board, and a distribution board for lighting.

|

|

|

MOL Plc. Danube Refinery – Modernization of Waste Burning Plant

|

To comply with the emission limits set by the EU’s stricter pollution policy, which was effective from 2005, an investment with extensive modernization started on a large scale within the Danube Refinery’s Wastewater Handling and Incinerator plants. A section of this was the alteration of the Waste Burning plant, in which a new 475 KW capacity grinder/mixer unit was installed with its auxilliary technical equipment. The Instrumentation and Electrical design work was prepared by Procoplan Ltd. The projects main features were:

- PLC system (Allen Bradley) installation for the control of the grinder/mixer unit and other new plant sections, and the preparation of PLC logic diagrams.

- IO number: xxxx.

- Software design for the modification for the user displays of the RSview32 SCADA HMI.

- Expansion of the existing transformer sub station.

- Refitting of the lighting system.

|

|

|

Mol Plc. Danube Refinery, Authority regulations technical requirements compliance project; Reviewing Safety Interlock Systems.

|

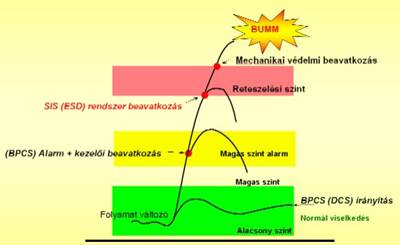

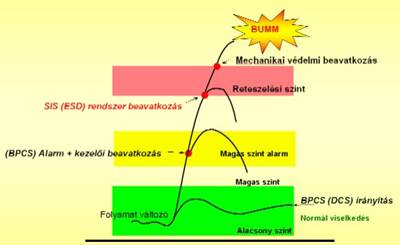

| The aim of this project is to improve the production availability and safety by ensuring compliance with the technical safety requirements and authority regulations, in accordance with the obligation prescribed by the law.

The function of Procoplan Ltd. in this was the reviewing of the safety systems, the SIL classification of the Safety Instrumented Functions (SIF) and proposing the necessary alterations (new SIFs, modifications of the existing SIFs and/or changing the Logic Solver if required.) |

|

|

Some more references in list form:

- MOL Plc. – Danube Refinery, AV-2 plant alterations – main contractor in Instrumentation (2009)

- MOL Plc. – Reconstruction of CGA Rail Car Loading Station, Detailed Design for Instrumentation (2008)

- MOL Plc. – Danube Refinery, Safety review of furnaces (approx. 180 pcs) and preparation of the Detailed Design for the necessary alteration of the Instrumentation (2003-2006)

- MOL Plc. – Revamp of the Claus-4 Sulphur Recovery Unit – Detailed Design for Instrumentation (2006)

- MOL Plc. – Reconstructions at the Naphtha production plants, preparation of instrumentation design plans as well as installation of the software configuration (2002-2003)

- MOL Plc. – Danube Refinery, GOK-2 plant, Revamping the Burner Management Systems of heaters 101-I and 101-II (2001)

- MOL Plc. – Fényeslitke, Modernization of the instrumentation and control of the Barátság-2 crude oil pumping and custody transfer (2000)

- MOL Plc. – Delayed Coker Unit, Instrumentation design plans with professional supervision (2000)

- MOL Plc. – Micro Crystal Wax Extracting plant – Instrumentation revamp (1999-2000)

- MOL Plc. – Naphtha Hydrotreating and Platformer plant, REF-100 unit design and installation of DCS application software configuration (1999)

- MOL Plc. – Revamp of the Units of Lube O Production, instrumentation basic-design as sub-contractor (1998)

- DUNASTYR Polystyrene Manufacturing C. Co. Ltd. – Replacement of DCS printers with serial data gathering – installation of data gathering system and its maintenance (1998-1999)